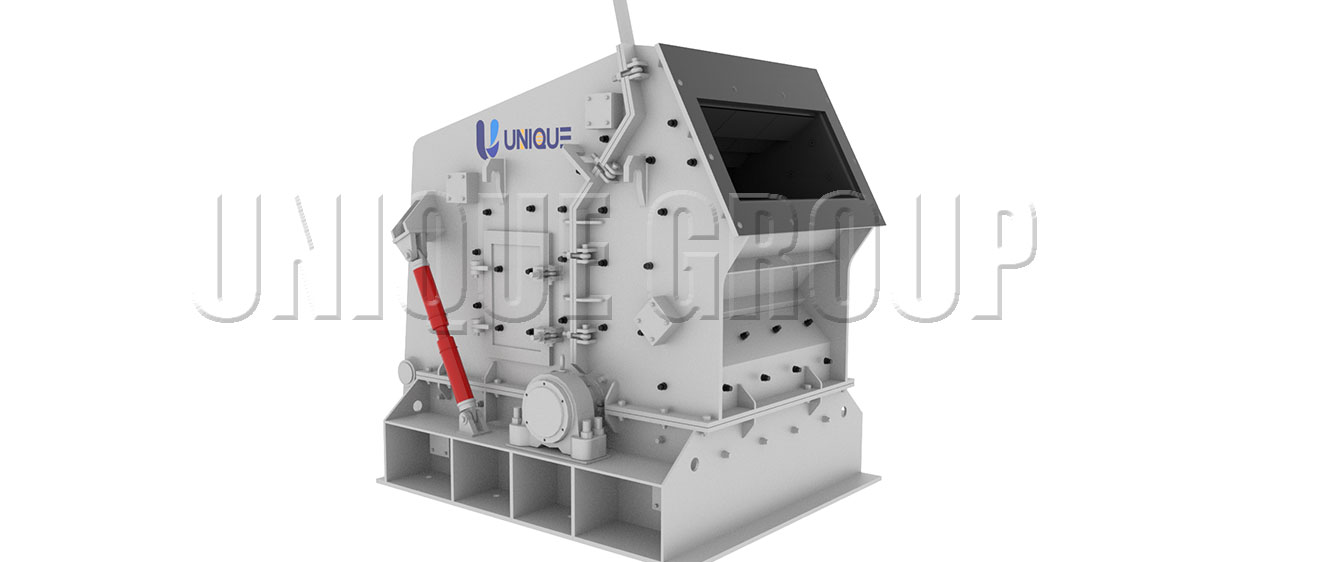

Impact Crusher

【Feeding Size】: ≤500mm

【Cone Crusher Output Size】: 5 -200 mm

【Capacity】: 40 – 400T/h

【Applicable materials】: Limestone, granite, construction wastes, marble, basalt, iron ore, river pebbles, shale, bluestone, coal, pebbles.

【Applicable Fields】: Widely used in various ore crushing, railways, highways, energy, cement, chemical, construction, and other industries.

What is the machine?: Inquiry Now

Impact crusher is a mechanical equipment that uses impact force to crush materials. It is widely used in mining, building materials, metallurgy, chemical industry and other fields. The following is a detailed introduction to impact crusher:

1. Definition

Impact crusher is a device named according to its working principle. Its core feature is to generate impact force through high-speed rotating rotor, so that the material is repeatedly impacted and crushed in the crushing chamber. This crushing method can effectively reduce energy loss and improve crushing efficiency.

2. Classification

A.PF series impact crusher:

PF impact crusher is a new generation of impact crusher developed by our company after absorbing advanced technologies at home and abroad and combining the specific industrial and mining conditions of the domestic sand and gravel industry. The impact crusher adopts new manufacturing technology and structural design. The finished product is cubic, without tension and cracks, and the particle shape is quite good. It can crush various coarse, medium and fine materials (granite, limestone, concrete, etc.) with feed particle size not exceeding 500mm and compressive strength not exceeding 350MPa. Impact crusher is widely used in various ore crushing, railways, highways, energy, cement, chemical industry, construction and other industries. The discharge particle size can be adjusted and the crushing specifications are diversified.

PF series impact crusher features:

1. The impact crusher has a large feed opening, a high crushing chamber, and is suitable for materials with high hardness, large block size, and less stone powder;

2. The gap between the impact plate and the hammer of the impact crusher can be easily adjusted, effectively controlling the particle size of the discharged material, and the particle shape is good;

3. The impact crusher has a compact structure, strong machine rigidity, and a large moment of inertia of the rotor;

4. The high-chromium hammer of the impact crusher is impact-resistant, wear-resistant, and has a large impact force;

5. The impact crusher has a keyless connection, which is convenient for maintenance and economical and reliable;

6. It has complete crushing functions, high productivity, low wear of machine parts, and high comprehensive benefits.

B. PFW European version series impact crusher:

PFW European version series impact crusher is a rock and mineral processing equipment commonly used in the world, and has become a popular crusher. The rotor is the "heart" of the machine and plays a vital role in its work. Future Machinery has developed and produced heavy-duty rotors with sturdy structures to obtain higher moments of inertia. Highly wear-resistant materials and larger crushing chambers have continuously made breakthroughs in the performance of the crusher. It is used in metallurgy, mining, cement, chemical industry, refractory materials and ceramics and other industrial sectors. It is widely used in highway construction, water conservancy projects, building gravel, machine-made sand processing and other fields. It is very suitable for crushing various soft and medium-hard ores for coarse, medium and fine crushing.

PFW European version impact crusher features:

1. Improved adjustment device, more convenient operation.

2. Adopting the most advanced manufacturing process and selecting high-quality materials.

3. The three-chamber crushing of this equipment is deeply loved by users in fine and ultra-fine crushing operations.

4. The two-chamber crushing of this equipment can simplify the process flow in coarse and medium crushing operations.

5. Heavy-duty rotor design and strict testing methods ensure high-quality rotors.

3. Application scenarios

Impact crushers are widely used in the following fields:

Mining: used for crushing ore, rock and other materials.

Building materials: used for the production of sand and gravel aggregates, cement clinker, etc.

Metallurgical industry: used for crushing metal ores and smelting waste.

Chemical industry: used for crushing chemical raw materials and waste.

Infrastructure construction: such as aggregate production in road and railway construction.

4. Equipment advantages

High efficiency and energy saving: Through high-speed impact crushing, the crushing efficiency is high and the energy consumption is low.

Uniform particle size: The particle size distribution of the crushed material is uniform, which is convenient for subsequent processing.

Wide range of application: It can handle materials of different hardness and has strong adaptability.

Good environmental protection: The equipment has low operating noise and small dust pollution.

Impact crusher is an efficient, energy-saving and environmentally friendly crushing equipment. With its excellent performance and wide application fields, it plays an important role in industries such as mining and building materials. If you have crushing-related needs, impact crusher will be an ideal choice.

How does it works?: Inquiry Now

How does impact crusher work?

Impact crusher is an efficient crushing equipment, and its working principle is based on the impact crushing of materials by high-speed rotating rotors. The following is the working principle and characteristics of impact crusher:

1. Basic working principle

The impact crusher impacts and crushes the material through the plate hammer on the rotor. The specific process is as follows:

Feeding: The material enters the crushing chamber from the feed port.

Impact crushing: The plate hammer on the high-speed rotating rotor produces high-speed impact on the material to crush it preliminarily.

Rebound and re-crushing: The crushed material is thrown to the impact plate along the tangential direction and crushed again under the action of the impact plate.

Circular crushing: The material repeatedly impacts between the plate hammer and the impact plate until it reaches the required particle size and is finally discharged from the discharge port.

2. Core components and functions

Rotor: The rotor is equipped with a plate hammer, which is the main component of crushing. Its high-speed rotation provides impact force for the material.

Plate hammer: It directly contacts the material and completes the crushing through high-speed impact.

Impact plate: Located at the other end of the crushing chamber, it is used to rebound the crushed material and improve the crushing efficiency.

Crushing chamber: The main space for material crushing, its shape and size affect the crushing effect.

3.Adjustment method

The discharge particle size of the impact crusher can be adjusted in the following ways:

Rotor speed: Increase or decrease the rotor speed to change the degree of material crushing.

Gap between the impact plate and the plate hammer: The gap is adjusted through a mechanical or hydraulic system to control the discharge particle size.

Summary

The impact crusher uses a high-speed rotating rotor and plate hammer to impact and crush the material, and combines the action of the impact plate to achieve multiple crushing, which has the advantages of high efficiency, energy saving, and high crushing ratio. Users can adjust equipment parameters according to specific needs to meet different production requirements. This equipment is widely used in building materials, mining, chemical industry and other fields.

Solutions: Inquiry Now

Crushing solution of impact crusher:

The application of impact crusher in fixed crushing station has significant advantages, especially when dealing with large-scale and continuous material crushing tasks. The following is an analysis of the application of impact crusher in fixed crushing station:

1. Application scenario

The impact crusher is mainly used in the following scenarios in fixed crushing station:

Sand and gravel aggregate production: such as the crushing of limestone, granite and other materials in highway and railway construction to produce sand and gravel aggregates that meet specifications.

Mining: In the crushing and processing of metal and non-metallic ores, impact crusher can be used for the crushing of medium hardness materials, such as iron ore, basalt, etc.

Construction waste treatment: crushing construction waste into recycled aggregates for road paving or building materials production.

Industrial solid waste treatment: such as the crushing of coal gangue and slag for environmental protection and resource recycling.

2. Advantages

The impact crusher has the following advantages in fixed crushing stations:

Efficient crushing: Through the impact of the high-speed rotating rotor and the hammer, as well as the synergistic effect of the impact plate, efficient crushing is achieved.

Energy saving and environmental protection: Low energy consumption during the crushing process, simple equipment structure, and easy maintenance.

Strong adaptability: Suitable for a variety of medium-hard materials, such as limestone, quartz sand, coal gangue, etc.

Good particle shape: The material after crushing is in a cubic shape with reasonable grading, which is suitable for the construction and building materials industry.

Flexible adjustment: By adjusting the rotor speed, the gap between the impact plates, etc., the particle size of the output can be flexibly controlled to meet different needs.

3. Actual cases

Case 1: Application of impact crusher in Hubei construction

In a large construction project in Hubei, the impact crusher was used for the production of sand and gravel aggregates in highway construction. Its efficient crushing capacity and good particle shape control significantly improved the aggregate quality and production efficiency.

Case 2: Construction waste treatment

In the construction waste treatment project, the impact crusher was used to crush waste concrete and bricks into recycled aggregates. These recycled aggregates are used for road paving and building materials production, realizing resource utilization.

4. Differences from mobile crushing stations

Fixed crushing stations: Impact crushers are mainly used for long-term, large-scale material processing in fixed crushing stations. Its equipment is fixedly installed, with stable production capacity, and is suitable for processing high-hardness and medium-hardness materials.

Mobile crushing station: Suitable for mobile operations, such as mining, temporary treatment of construction waste, etc. Its equipment can be moved quickly and has strong adaptability, but its processing capacity is relatively limited.

5. Precautions

Material moisture: Impact crushers are suitable for processing materials with low moisture content. If the moisture content is too high, drying equipment may be required.

Wear problems: Components such as impact plates and hammers are prone to wear and need to be regularly inspected and replaced.

Equipment maintenance: Equipment in fixed crushing stations requires regular maintenance to ensure stable operation and extend service life.

Summary

In fixed crushing stations, impact crushers are widely used in sand and gravel aggregate production, mining, and construction waste treatment due to their advantages such as efficient crushing, energy saving and environmental protection, and good particle shape. Its fixed design is suitable for large-scale, continuous operations, which can significantly improve production efficiency and reduce costs. At the same time, reasonable configuration and maintenance of equipment are the key to ensure its long-term and efficient operation.

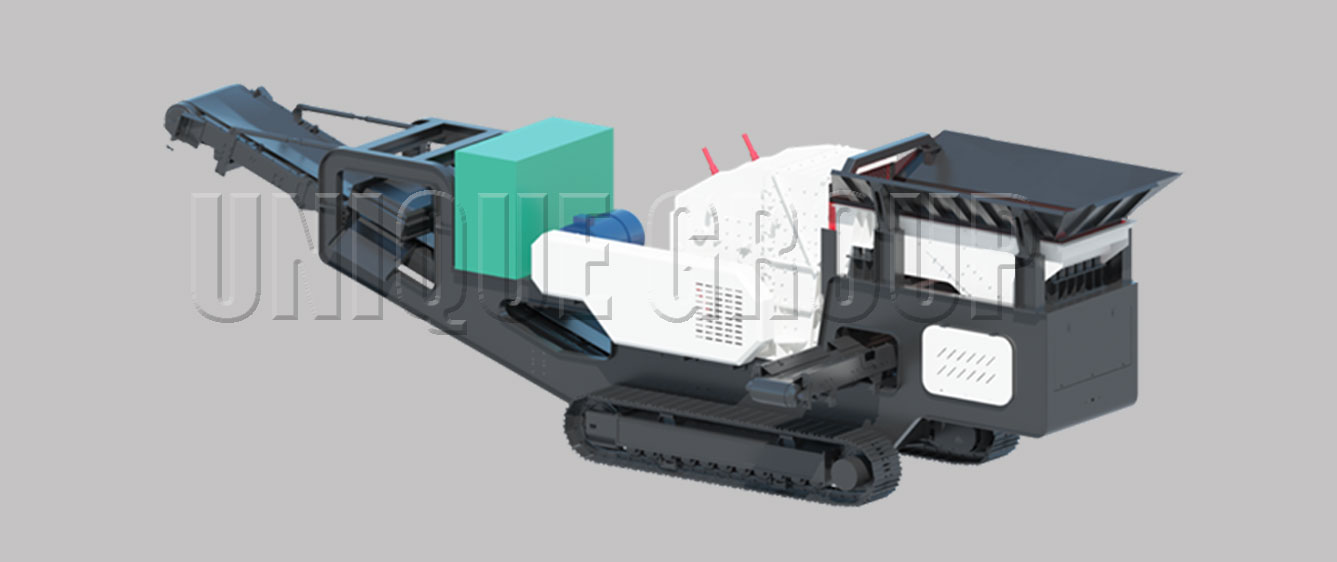

Mobile impact crushing station

Mobile impact crusher plant is a modern mechanical equipment that integrates crushing, screening and conveying functions. Due to its flexibility and efficiency, it is widely used in many fields. The following is a detailed description from the aspects of definition, technical characteristics, application scenarios, advantages and disadvantages and actual cases.

1. Definition and characteristics

Mobile impact crushing station is an impact crusher installed on a mobile chassis, which can be quickly transferred and is suitable for mobile operations. Its characteristics include:

Modular design: The equipment consists of multiple modules and can be flexibly configured according to needs.

Efficient crushing: Efficient crushing is achieved through the impact of the impact plate and hammer.

Intelligent control: Some equipment is equipped with an intelligent electronic control system, which can be remotely operated and monitor the operating status in real time.

Strong adaptability: The chassis adopts a high-strength structure to adapt to complex terrain without the need for additional infrastructure.

2. Application scenarios

Mobile impact crushing stations are widely used in the following fields:

Construction waste treatment: Crushing construction waste into recycled aggregates for road paving or building materials production.

Mining: used for ore crushing, especially the processing of liquid stone.

Highway and railway construction: provide sand and gravel aggregates that meet specifications.

Environmental protection engineering: handle industrial solid waste and waste materials in mineral processing.

3. Technical features

Crushing chamber optimization: reasonable design of impact crushing chamber, large crushing ratio and low energy consumption.

Oil-electric dual-purpose power system: supports flexible switching of power forms and reduces operating costs.

Crawler or tire drive: crawler chassis has strong adaptability, and tire chassis is more flexible in transfer.

Intelligent control system: some equipment supports remote operation and fault warning to improve work efficiency.

4. Advantages and disadvantages analysis

Advantages:

High flexibility: can quickly transfer and adapt to different terrains and environments.

High efficiency and environmental protection: high crushing efficiency, low energy consumption, and meet environmental protection requirements.

Strong adaptability: suitable for a variety of materials, such as ore, construction waste, sand and gravel, etc.

Easy operation: modular design facilitates installation and maintenance, reducing labor intensity.

Disadvantages:

High equipment cost: mobile impact crushing station is expensive and has a large initial investment.

Wear of wearing parts: Wearing parts such as hammers and impact plates wear quickly and need to be replaced regularly.

Limited processing capacity: Compared with fixed crushing stations, mobile crushing stations may have lower production capacity.

5. Actual case

Case: Mining

In the construction of roads and bridges in Peru, mobile impact crushing stations are used to crush gravel aggregates. Its efficient crushing capacity and flexible mobility significantly improve construction efficiency.

6. Summary

Mobile impact crushing stations have become important equipment in mining, construction waste treatment and other fields due to their flexibility, efficiency and adaptability. Its intelligent design and modular configuration enable it to perform well in a variety of scenarios, but it is also necessary to pay attention to its high cost and replacement of wearing parts. Through reasonable configuration and maintenance, mobile impact crushing stations can bring significant economic and environmental benefits to users.

Crawler impact crusher

Crawler impact crusher is an efficient crushing equipment, widely used in construction waste treatment, mining, sand and gravel aggregate production and other fields. The following is a detailed description of the definition, working principle, technical characteristics, application scenarios, advantages and disadvantages and actual cases.

1. Definition and working principle

The crawler impact crusher is an impact crusher installed on a crawler chassis, which is highly flexible and adaptable. Its working principle is as follows:

Feeding: The material is fed into the silo by a forklift or excavator and initially screened by a screening feeder.

Crushing: Large pieces of material enter the impact crushing chamber and are crushed by the impact between the high-speed rotating hammer and the impact plate.

Screening and conveying: The crushed material is graded by a vibrating screen, and the material that meets the particle size requirements is directly discharged, and the unqualified material returns to the crushing chamber for further crushing.

2. Technical features

The crawler impact crusher has the following technical advantages:

Efficient crushing: It adopts a heavy-duty rotor structure and a large-capacity crushing chamber, with a large crushing ratio and excellent particle shape.

Flexible adjustment: The discharge gap can be flexibly adjusted according to the finished product particle size requirements to meet different specifications.

Intelligent design: Equipped with a hydraulic adjustment device and an intelligent control system, remote operation and real-time monitoring can be achieved.

Modular design: The cavity liner and impact plate design with strong interchangeability extend the service life and reduce maintenance costs.

Environmental protection and energy saving: low noise design, reducing dust pollution, in line with green environmental protection requirements.

3. Application scenarios

Crawler impact crusher is suitable for a variety of fields:

Construction waste treatment: crushing construction waste into recycled aggregates for road paving or building materials production.

Mining: used to crush pebbles, limestone, basalt and other ores to meet the crushing needs of medium-hard materials.

Sand and gravel aggregate production: provide good quality sand and gravel aggregates for highway and railway construction .

Metallurgy and energy industry: used for crushing and processing of metal ores and coal.

4. Advantages and disadvantages analysis

Advantages:

Strong flexibility: crawler chassis design, can quickly transfer, adapt to a variety of terrains.

Efficient crushing: large crushing ratio, good finished product particle shape, suitable for a variety of materials.

Environmental protection and energy saving: low noise, low dust emission, in line with environmental protection requirements.

Intelligent operation: equipped with hydraulic system and intelligent control system, easy to operate.

Disadvantages:

High equipment cost: crawler impact crusher has a high purchase cost and a large initial investment.

Frequent replacement of wearing parts: wearing parts such as hammers and impact plates wear quickly and need to be replaced regularly.

Limited processing capacity: compared with fixed crushing stations, the production capacity may be slightly lower.

5. Actual cases

Case 1: Resource utilization of construction waste

In the construction waste treatment project, Zhengzhou UNIQUE crawler impact crusher crushes waste concrete and bricks into recycled aggregates for road paving and building materials production. Its high-efficiency crushing capacity and flexible transfer significantly improve the efficiency of resource utilization.

Case 2: Mining

In the construction of roads and bridges in Mexico, crawler impact crushers are used to crush gravel aggregates, providing construction with sand and gravel aggregates that meet specifications while reducing the cost of aggregate transportation.

6. Summary

Crawler impact crushers have become important equipment in the fields of mining, construction waste treatment, etc. due to their high-efficiency crushing, flexible transfer, and environmental protection and energy saving. Although their cost is high and wearing parts are frequently replaced, they can bring significant economic and environmental benefits to users through reasonable configuration and maintenance.